Industrial Filter Textile Bags Polyester Pleated Dust Filter Bags for Steel Industry

Industrial filter textile bags polyester pleated dust filter bags for steel industry: 1, fiber, efficient filtration, re;

Basic Info

| Model NO. | textile dust bags |

| Filter Bag Sectional Shape | Round Bag |

| Filter Bag Environment | High-Temperature |

| Cartridge Installation | Vertical Lifting |

| Lamination | PTFE |

| Gram Weight | 750g |

| Transport Package | Plastic and Carbon Box |

| Specification | fiberglass |

| Trademark | DR. GREEN |

| Origin | China |

| HS Code | 7019909000 |

| Production Capacity | 50000PCS |

Product Description

Industrial filter textile bags polyester pleated dust filter bags for steel industry:

1, fiber, efficient filtration, reduce emissions and running resistance.

A. Filter bag manufacturers select fine fibers to increase the filtering area and reduce the filtering gap of filter materials, thus improving the filtering efficiency of filter materials, reducing the emission concentration and running resistance.

B. The filter material is produced by imported equipment, and the performance of the produced filter material is stable.

2. Post-treatment of filter materials guided by customers' working conditions.

According to the change of dust characteristics, the needle felt filter material is treated with different surface or coated with protective layer to meet the needs of customers under different working conditions.

3. The filter bag shall be manufactured in strict accordance with the national standard of GB12625-90 to ensure the qualified rate of products leaving the factory.

A. Elastic expansion ring and saddle pad (non-rubber ring) made of the same material filter material are adopted at the bag mouth, so as to avoid the rubber ring aging at high temperature and cause the filter bag to fall off.

B. The seam of the bag mouth shall be treated by dislocation to ensure the close joint between the bag mouth and the flower plate and avoid dust leakage from the flower plate hole.

C. the needle distance of the filter bag is 25 1, and the filter bag has no drop or float line, and the comprehensive strength of the seam of the filter bag is > 1000N.

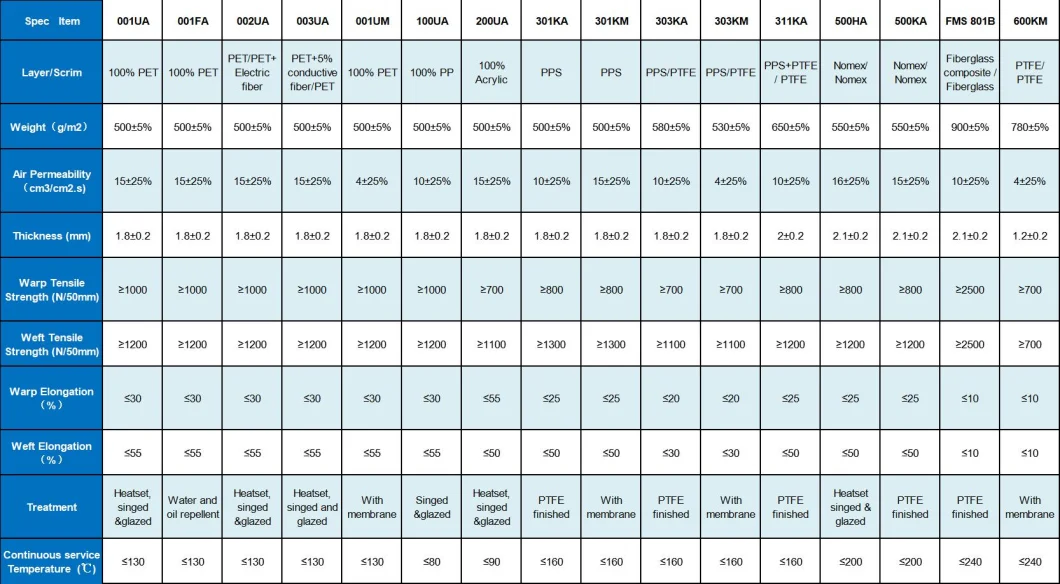

| Material | Gramage | Thickness | Working Temperature | Max. Surge Temperature |

| (g/m²) | (mm) | (ºC) | (ºC ) | |

| Polyester needle felt | 500 | 1.8 | ≤130 | 150 |

| PPS needle felt | 500 | 1.8 | ≤190 | 230 |

| Fiberglass | 1000 | 2.1 | ≤280 | 300 |

| Acrylic fibers | 500 | 2 | ≤160 | 180 |

| 800 | 2 | ≤280 | 300 |

You may also like

Send inquiry

Send now